Laser Cutting Machine - Truths

Wiki Article

On the subject of fashionable producing, the precision and efficiency of laser slicing technology are definitely video game-switching. Laser slicing machines have revolutionized industries by supplying a way of reducing materials with unparalleled precision. When you’ve at any time marveled in the intricate designs on metal or wondered how sophisticated shapes are generated so seamlessly, it’s often the work of the industrial laser cutting machine.

Enable’s get started with the fundamentals: a laser cutter can be a Instrument that employs a laser beam to chop supplies. This beam is incredibly concentrated and generates significant temperatures to soften or vaporize the fabric, making exact cuts. In contrast to classic strategies, which could use mechanical blades, a laser cutter offers a amount of precision that is almost unmatched. Picture endeavoring to carve a delicate sample that has a hammer—Obviously, a laser cutter is a good deal additional refined!

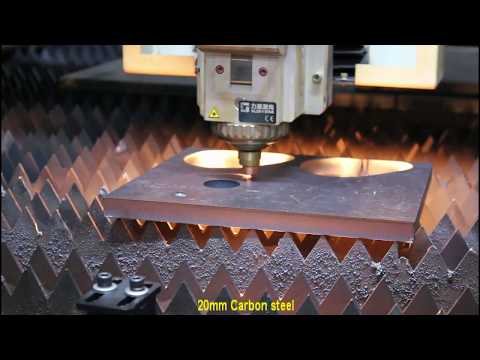

Industrial laser chopping will take this technological know-how to the following amount, giving alternatives for giant-scale functions. These machines are built to deal with hefty elements and superior creation volumes, ensuring that even one of the most demanding jobs are concluded with large performance. Think of it because the difference between utilizing a precision knife for fragile paper crafts and a strong observed for slicing by thick wood.

Not known Details About Cnc Laser Cutting

On the globe of CNC laser chopping, the “CNC” means Computer system Numerical Command. This know-how allows for automated and hugely specific cuts by subsequent digital layouts. Should you’ve at any time utilised a computer to attract and after that witnessed that drawing arrive at lifestyle, CNC laser slicing will work in an analogous way, translating digital designs into Actual physical cuts. It’s like aquiring a virtual designer While using the precision of a laser.

On the globe of CNC laser chopping, the “CNC” means Computer system Numerical Command. This know-how allows for automated and hugely specific cuts by subsequent digital layouts. Should you’ve at any time utilised a computer to attract and after that witnessed that drawing arrive at lifestyle, CNC laser slicing will work in an analogous way, translating digital designs into Actual physical cuts. It’s like aquiring a virtual designer While using the precision of a laser.Laser Cutting Systems for Beginners

Precision laser cutting is not pretty much producing cuts; it’s about making them appropriate each and every time. The laser is often adjusted to realize distinct depths and widths, ensuring that each cut is precisely where it ought to be. This is certainly crucial for applications exactly where even a slight deviation could lead to sizeable problems. Imagine it like a surgeon’s scalpel, the place precision is not only critical but Completely vital.

Precision laser cutting is not pretty much producing cuts; it’s about making them appropriate each and every time. The laser is often adjusted to realize distinct depths and widths, ensuring that each cut is precisely where it ought to be. This is certainly crucial for applications exactly where even a slight deviation could lead to sizeable problems. Imagine it like a surgeon’s scalpel, the place precision is not only critical but Completely vital.Laser cutting gear is available in many sorts, Each and every tailored to particular requires. Whether You'll need a small desktop product for hobby jobs or an enormous industrial device for manufacturing unit use, there’s a laser cutting Alternative to choose from in your case. These equipment range in electrical power, pace, and capabilities, so it’s essential to select the correct one particular for the individual software.

Sheet steel laser cutters absolutely are a special category of laser cutting machines intended especially for reducing metal sheets. They can be commonly used in industries ranging from automotive to aerospace due to their power to deal with steel with precision and pace. Image a sheet of metal similar to a blank canvas, and also the laser cutter since the artist who produces elaborate and exquisite patterns with outstanding accuracy.

Laser chopping discover here companies are One more crucial aspect of this technology. Not Absolutely everyone wants to take a position in their own laser cutting device, particularly when they only want occasional cuts or absence the House for such machines. A lot of businesses present laser chopping providers in which you can send your models and have them Slash with higher precision. It’s like outsourcing your artwork to a skilled Skilled.

Laser reducing techniques combine different components to deliver the specified effects. With the laser resource towards the cutting mattress, and the Regulate application, each individual part of the system operates alongside one another to ensure a flawless operation. It’s a tiny bit similar to a symphony orchestra, the place Every musician has a particular job, and only by Doing the job jointly do they make a harmonious overall performance.

When it comes to laser cutting technological innovation, the evolution continues to be rapid and remarkable. Originally utilised largely for cutting metals, these devices now manage an array of materials including plastics, wood, and in many cases fabrics. This versatility will make laser chopping technology a valuable Instrument in many industries. Envision possessing a Swiss Army knife that may take care of nearly any product—This is often what modern laser reducing technologies features.

The accuracy of laser reducing machines is truly extraordinary. They can cut supplies to inside of microns on the supposed style, guaranteeing that even one of the most intricate information are preserved. This amount of precision is especially important in industries the place actual measurements are important. view more Think about it given that the distinction between a tailor-made go well with and off-the-rack outfits—the healthy is simply excellent every time.

Some Known Questions About Sheet Metal Laser Cutter .

An additional benefit of laser chopping technologies is its performance. Contrary to common slicing strategies That may demand several methods or equipment, laser chopping often completes the job in one go. This don't just hurries up manufacturing but will also lessens substance squander. It’s like aquiring a substantial-speed practice that gets you for your location quickly and effectively without any avoidable stops.Inside the context of industrial programs, the robustness of laser cutting equipment is important. These equipment are designed to endure the demands of constant operation, frequently operating 24/seven in superior-volume settings. Their durability makes certain consistent overall performance and reliability, that is important for keeping manufacturing schedules. It’s like getting a weighty-duty truck that reliably provides merchandise working day soon after day.

One of many remarkable elements of laser chopping is its ability to make cleanse and precise edges. This decreases the need for write-up-processing, which include sanding or ending, which may be time-consuming and dear. The result is usually a sleek, finished product or service That always needs negligible added perform. Think about ending a craft venture without having glue spills or tough edges—it’s that thoroughly clean!